Extruded aluminum profile is one of the lightest and most versatile systems available for building structures and machinery.

Here is a technical article in which we give you:

- All the data on how much our profile weighs

- How you can calculate the mass of different cross-sections, materials and lengths yourself

How much does our aluminum profile weigh?

If you need the data immediately for a project, here you have the data table of all the profiles we have in Bitfab Parts.

The “weight” of the profiles, or more correctly, their mass, is expressed in units of mass per unit length, e.g. in kilograms per meter. Thus, the mass of a profile bar of any length can be calculated.

The weight ranges from 0.44 kg/m of the 20×20 V-Slot type profiles to 3.11kg/m of the 40x80mm type B profile.

The table with all the mass per unit length data of our profiles is as follows:

| Profile | Mass |

|---|---|

| 20×20 V-Slot profile | 0.44 kg/m |

| 20×40 V-Slot profile | 0.80 kg/m |

| Profile 30×30 type B | 0.86 kg/m |

| Profile 30×60 type B | 1.52 kg/m |

| Profile 40×40 type B | 1.78 kg/m |

| Profile 40×80 type B | 3.11 kg/m |

Automatic profile weight calculator

We have made a web calculator so that you can quickly find out the weight of any type and length of profile:

How to calculate the weight of my profile? The formula

With the data in the table above, the mass of any length and type of profile can be calculated easily.

If, for example, I have a meter and a half (1.5m) of 20x20mm V-Slot profile, its mass is:

\[ m = 1.5 \text{m} \text 0.44 \text{kg/m} = 0.66 \text{kg} \]A second example, if I have 80cm of 40x80mm profile type B, changing the units to meters and with the table above, I will have:

\[ m = 0.8 \text{m} \cdot 3.11 \text{kg/m} = 2.49 \text{kg} \]How to calculate the mass of any profile section?

We have given you the data to quickly calculate the mass of the most common aluminum profiles, from the selection we have in our store.

In order to calculate the weight of any aluminum section (different types of profiles, customized sections, unique sections…), we show you here the method we use to calculate the weight of any type of profile using CAD software.

How much does aluminum weigh? The density of aluminum

The first thing we need to know is the density of the material from which the profiles are made, aluminum:

The density of aluminum is 2700 kg/m3, or 2.7 g/cm3 (also 2.7 times the density of distilled water).

This density refers to pure aluminum and is the one we will take into account in our calculations, although you should know that there are different alloys used to manufacture aluminum profiles (e.g. aluminum 6060-T5 or 6060-T5) that may have a slightly different density.

Just for comparison, keep in mind that the density of steel is 7850 kg/m³, which is why aluminum is such a popular material for creating lightweight structures.

Calculating the area of an aluminum profile section

The second piece of information we need to calculate the weight of a profile is its cross-sectional area.

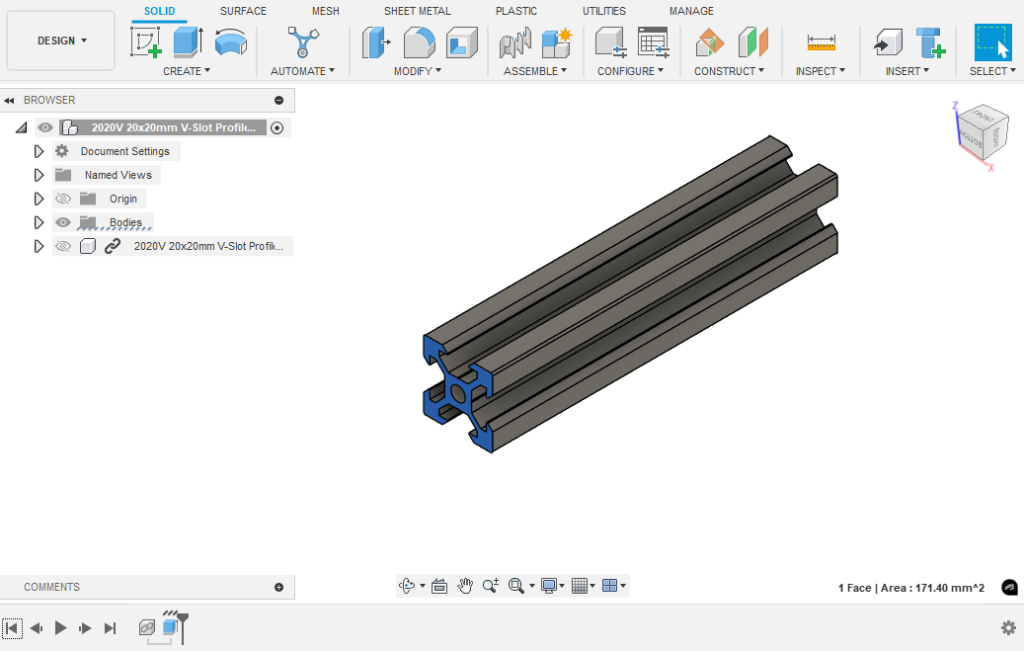

It is a very complicated data to calculate by hand for most of the sections using slotted profiles, so we have to resort to CAD design programs, which give us this type of data:

Calculation of mass per unit length

To calculate the mass of one meter of profile, we need to operate:

\[m = \rho \cdot A \cdot L \]where:

- \(m\) is the mass of the profile

- \(\rho\) is the density of the material

- \(A\) is the area of the section

- \(L\) is the length of the profile (we will choose one meter to obtain the mass per meter of profile).

So, with the data we have:

- The density of aluminum, \(\rho\), is 2700 kg/m3.

- The area, \(A\), of our section, 171.40mm2, which we can convert to square meters A = 171.40mm2 = 1.7140 – 10-4m2

And the result is:

\[m = \rho \cdot A \cdot L = 2700 \text{kg} /\text{m}^3 \cdot 1.7140 \times 10^{-4} \text{m}^2 \cdot 1 \text{m}= 0.46 \text{kg} \]Which as you can see is very similar to the empirical result of our profile (0.44kg). There may be small differences depending on the type of profile, sections, alloys, how the calculations have been made, etc.

The mass or weight debate: which term is correct?

If you have noticed, throughout the article we have used the terms mass and weight more or less interchangeably.

Which is the correct one?

Weight actually refers to a type of force (the force exerted by the Earth on an object) and would be measured in units of force (e.g. in newtons or kiloponds). For this reason, it is not most correct to refer to the mass of objects, or profiles, as their weight.

We prefer to say mass, for example, expressed in kilograms, which is the more specific term. It could also be tons, or any other unit of mass.

Colloquially, the normal thing to say is “weight”, so we can’t say it’s an incorrect term, the priority here is to understand each other.

And if you are surprised by this point I understand, the goal is not to be pedantic. The mission of this kind of articles is to divulge about technical aspects in a way that we all can learn, we wanted to clarify this issue as well.

Did you like this article?

As you have seen, we have a passion for technical topics and so we like to explain and tell about them.

I hope you found the content useful, if after making your calculations about the weight of your profiles you need components you can go through our online store aluminum profile, or if you have a project you can ask for help on our contact page.

And if you have any questions or suggestions about the content, you always have the comments of the article to raise them.